Our expertise

There is the traditional

And the exception

It is the growing awareness of the environment that is behind Aventec. Its range of products is differentiated from the competition by the use of an eco-innovative technology that allows Aventec to offer its customers a solution combining quality of use and environmental quality "

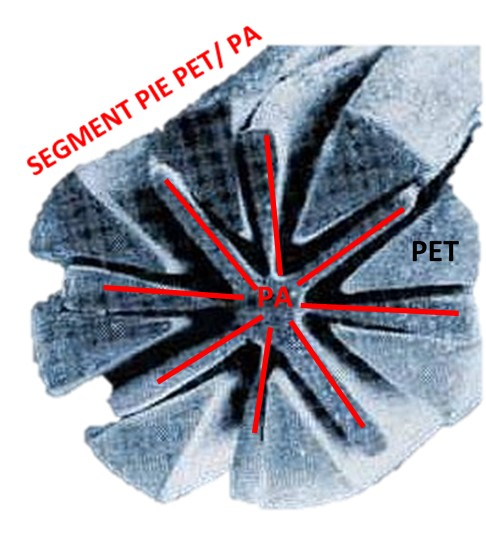

Filaments of about 2 Dtex are extruded, stretched and randomly deposited on a batting apron. These are maintained under suction and then and at the same time separated and intermingled by a hydraulic linkage (HE) in the up-down direction thus obtaining a product of titles and extremely strong.

This veil thus produced must be softened, dyed and undergo other treatments before making.

What is our microfilament?

Given our development of microfilament in recent years and the limits reached by microfiber, it is important to have a technical approach to really compare what is comparable to obtain a result in line with the need field. The elements and criteria that come to the top of the table are:

- The smoothness, to pass in all the irregularities of the supports without risk

- The density of filaments per m2, large absorption capacity

- The mechanical force, the particles grease, dust etc ... are trapped in the dense network of continuous filaments

- Electrostatic force, when dry, microfilaments are positively charged by friction and attract negatively charged organic dusts

Characteristics of our microfilaments

Our microfilament is a fiber whose title is less than 1 Dtex. The dtex is the value in grams of 10,000 m of yarn. Thus 10 km of wire weigh less than one gram and the smaller the diameter of the wire, the more effective it is. Number, length, and diameter are the three most important parameters in media performance. For comparison, a hair has a diameter of 60 Microns, wool has 20 Microns, most microfibres have 10 Microns and our microfilaments is between 1.5 and 2.5 Microns, we can speak about Nano.

Nature of our microfilaments

Our microfilaments are made from Polyester and Polyamide in ratios ranging from 70/30 to 80/20. The polyester is hydrophobic and therefore, does not absorb water but lipophilic and therefore absorbs fats and oils. The polyamide is hydrophilic and lipophilic. However one of the great features of our wipes and the ability to absorb oil & water by capillarity and therefore allows a quick washing and drying at low temperature and first quality.

Aventec, the expertise of the professionl,

What were and still are our priorities,

- A high absorption capacity

- Dry cleaning without traces

- Minimize the use of detergents

- Reduce washing, temperature and water costs

- Increase the life and reach more than 600 washes.

- Recycling, 100% in the plastic injection industry.

- Provide the professional world, with the biggest linen renters as a target

- Produce 100% made in France, from granules to finished products.

- Ensuring the continuation of microfibers with innovative technology

- Replace the washcloths produced by polluting and consuming water.

- Define precisely the products with their characteristics by sector of activity.

- Increase the ergonomics of work, from the glass of champagne to the car body through the windows.

To date, Our continuous microfilaments are the best performers on the market in their respective categories due to their physical properties, their performance and their very low impact on the environment. In addition, they are made in France and are completely recyclable.